There’s something undeniably satisfying about sewing a patch onto your jacket, that tiny moment when the needle pops through the fabric, and you think, “Yep, this is going to look mean.” Sewn on patches have this old-school reliability that Kiwis just vibe with. No peeling. No popping off mid-mission. No dramas.

Whether you’re decking out denim jackets for your band, giving your work shirts a professional lift, or adding some flavour to your weekend caps, sew-on patches deliver a level of stay-there-mate performance that iron-ons and adhesives simply can’t always guarantee.

Nowadays where we all love shortcuts, sometimes the classic method is still the GOAT. Before diving into the whole “how to sew a patch on a jacket” thing, or whether you can sew patches on hats without losing your sanity, let’s get into why sew-on patches still dominate in NZ’s apparel, streetwear, corporate, sports, and creative scenes.

What Exactly Are Sew-On Patches?

Sew-on patches (or sewn on patches for those of you punching keywords into Google like a champ) are patches made to be attached by stitching through the garment. No heat press magic. No sticky backs. Just thread, needle, and a bit of Kiwi craftiness.

You’ll find them used across:

- Custom patches for denim jackets

- Custom patches for clothing

- Patches for hats and caps

- Motorcycle vest patches

- Custom patches for hoodies and work shirts

- NZ custom patches for uniforms, clubs, and corporate staff

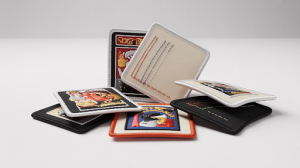

They come in every style imaginable, embroidered custom patches, woven patches, PVC custom patches, rubber custom patches, custom chenille patches, leather patches, and more.

If you’re new to the patch universe or want a full deep-dive into styles, history, and trends, Patch Makers NZ already has a solid primer here: What are Custom Patches – History, Types, Trends, and More!.

Why Sew-On Patches Are Still King in NZ

Let’s cut to the chase, Kiwis love stuff that lasts. From gumboots to Hiluxes, we like reliability. Sew-on patches fit that energy.

1. They Survive the NZ Lifestyle

Iron-on patches and heat-press custom patches are sweet, until you throw them into a hectic Kiwi routine involving:

- rugby trainings

- weekend missions

- coastal road trips

- unpredictable rain

- over-washed work uniforms

Sewn on patches? They tank all of it with zero sooks.

2. They Work on Tricky Fabrics

Leather jackets, motorcycle vests, thick canvas, nylon bags, anything that might laugh at an iron-on patch is no match for stitching.

Perfect for:

- custom patches for leather vest

- custom leather patches for jackets

- custom patches for backpacks

- airsoft custom patches with velcro removed

- patch panel custom patches sewn directly

3. They Look Premium

There’s a clean, professional finish when a patch is stitched in properly. Embroidered custom patches, woven patches, and PVC patches look especially premium when sewn on compared to adhesive options.

4. Patches Don’t Go Missing

No peeling. No surprise detachments. No going walkabout in the dryer. Just staying put, exactly how you stitched them. This reliability is why sewn on custom patches remain the default choice for:

- schools

- tradies

- hospitality uniforms

- streetwear brands

- motorcycle clubs

- event merch

- sports teams

How to Sew a Patch on a Jacket (Without Losing the Plot)

Let’s keep it simple and Kiwi-friendly.

1. Place the Patch

Line it up where you want it. Shoulders, sleeves, chest, back, whatever suits your design.

2. Pin It or Temporary Stick It

Some pros use fabric glue dots or double-sided tape so the patch doesn’t shift like a naughty possum.

3. Thread It Like a Pro

Match thread colour to the patch edge for that clean factory look.

4. Start Sewing the Edges

Small stitches. Close together. Go around the perimeter.

5. Knot the Back

Tie it tight and trim it. Done.

And yes, this same method works for:

- how to sew a patch on a hat

- how to sew patches on jackets (plural, for the overachievers)

- sew patches on hats (curved surfaces need patience)

When Sew-On Beats Everything Else

Here’s when sewn on patches are your best mate:

- You want premium branding for work shirts

- You’re creating large custom patches for jackets

- You need durable custom patches for backpacks

- You’re making motorcycle custom patches

- You need high quality custom patches that can take a beating

- You’re after custom patches wholesale for long-term use

And yes, sew-on is the best option for:

- no minimum custom patches

- custom patches bulk

- cheap custom patches no minimum

- embroidered custom patches iron on (you can still sew these)

- leather custom patches

- custom sequin patches (they NEED stitching)

Choosing the Right Sew-On Patch Type

Before you go threading needles like you’re about to join your nan’s sewing circle, let’s get real about patch types. Each one behaves differently when sewn onto clothing, jackets, hats, backpacks, and vests and picking the right one makes ALL the difference.

Here’s the lowdown:

1. Embroidered Custom Patches

The classics. These are the “everyone knows me” patches of the custom world.

- Timeless

- Textured

- Perfect for branding, uniforms, sports teams

- Easy to sew

- Available in no minimum custom embroidered patches too

Whether you’re making custom embroidered patches NZ, large custom embroidered patches, or cheap custom embroidered patches, sewing gives them a clean, premium frame.

2. Woven Patches

These beauties of woven patches are for design geeks who want detail sharp enough to impress their mates.

- Clean lines

- Detailed logos

- Great for small custom patches

- Lightweight and easy to sew

3. PVC Custom Patches & Rubber Custom Patches

PVC patches bring the tough-as energy. Think rain, mud, sweat and still standing.

- Durable

- Waterproof

- Popular for outdoor gear, airsoft clubs, and tactical crews

- Slightly thicker, but totally sewable

Heaps of people assume PVC patches must be stuck or Velcroed, nope, you can stitch them on and they look mint.

4. Leather Patches (Faux or Real)

Talk about premium vibes. Leather patches are popular for:

- leather jacket custom patches

- custom leather patches for clothing

- custom leather patches for hats

- motorcycle vest branding

Sewing works beautifully here since heat pressing leather is a risky business that can crack, bubble, or permanently damage the material.

5. Chenille Patches

Varsity jacket energy. Streetwear gold. Ultra soft but visually bold.

- Thick

- Trendy

- Perfect for hoodies, jackets, varsity apparel

Yes, you can absolutely sew on custom chenille patches and custom chenille patches wholesale, most people do.

Sew-On Patches for Different Apparel & Uses

Not all gear is stitched the same. Let’s break down where sewn-on patches shine brightest.

1. Jackets & Outerwear

This is where sew-on patches truly live their best life.

- denim jackets

- varsity jackets

- motorcycle vests

- leather jackets

- heavy winter wear

Sewing ensures longevity, even for large custom patches for jackets and letterman jacket custom patches. If you’re wondering how to sew a patch on a jacket, the quick version is: pin, stitch, secure, flex. Done.

2. Hats & Caps

This always scares beginners, curved surfaces aren’t exactly friendly. But sewing patches on hats is easier than you think:

- Use strong thread

- Stitch slowly

- Keep tension consistent

Perfect for:

- brand caps

- merch hats

- sports team caps

- streetwear drops

Also, how to sew a patch on a hat is one of the most searched NZ queries and yes, it works with embroidered, woven, rubber, and even small leather patches.

3. Work Shirts & Uniforms

Tradies, hospitality squads, construction crews, sew-on custom patches are the only option that can handle daily washing, sweat, and rough use.

Perfect for:

- custom patches for work shirts

- custom patches for uniforms

- high quality custom patches for corporate brands

Sewing ensures the branding looks crisp for years, not weeks.

4. Hoodies & Streetwear

Sewn patches hit differently in NZ’s streetwear scene. Small patch on the chest? Nice. Big patch on the sleeve? Fire. Whole back piece? That’s a statement. Sew-on patches work best for custom patches for hoodies, motorcycle custom patches, custom patches for vests, and custom patches for jeans.

Why NZ Brands Love Sew-On Patches for Bulk Orders

Whether you’re a clothing label, merch seller, or uniform supplier, sewing becomes a practical advantage when ordering:

- custom patches in bulk

- bulk custom patches

- wholesale custom patches

- cheap custom patches no minimum

- no minimum custom patches

Sew-on patches offer:

- easy mass application

- universal compatibility

- lower branding costs

- cleaner finish on all fabrics

Plus, NZ businesses often need a mix of materials, PVC, embroidered, leather, woven, and sewing is the only method that works for all of them without constant patch type adjustments.

How Patch Makers NZ Helps You Get the Best Sew-On Patches

We’re not just another “custom patches maker” or random “custom patches near me” Google result. Patch Makers NZ is the Best Patch Maker for sew-on patches. Whether you’re ordering one-off custom embroidered patches or large custom patches for jackets, we’ve got your back. And since you’re already deep into the patch world, another great read to level up your patch knowledge is: Everything About Custom Patches – Types, Styles and Uses.

Sew-On Patch Mistakes Beginners Make (And How to Dodge Them)

Let’s save you some headaches:

1. Using Weak Thread

You’re stitching on a patch, not fixing a sock. Use strong thread.

2. Skipping the Pinning Step

If you don’t secure the patch before stitching…

It will move.

It will annoy you.

You will unpick it and start again.

3. Choosing the Wrong Patch Type

Not all patches like being bent, flexed, or stretched.

PVC is thick. Chenille is fluffy. Leather is stiff.

Each one needs patience.

4. Sewing Too Close to the Inner Edge

Your patch might lift. Stick to sewing around the outer border or merrow edge.

FAQs

Are sew-on patches better than iron-on patches?

Sew-on patches last longer, survive washing better, and work on every fabric,including leather, nylon, wool, denim, and canvas. Iron-on patches are great for quick application, but sewing gives the strongest, longest-lasting hold. Many NZ brands use both: iron-on to position, sewing to secure.

Can you sew on an iron-on patch?

Yes, 100%. In fact, most people do. Iron-on backing helps keep the patch in place, and sewing strengthens it so it never peels off. This works especially well for jackets, uniforms, backpacks, hats, and motorcycle vests.

What’s the best way to sew a patch onto a jacket?

Pin the patch where you want it, thread a strong needle, and sew along the outer border using small, tight stitches. Heavy jackets (leather, denim, varsity) need thicker thread and patience but the result looks super clean and professional.

Can I sew patches on hats or caps?

Yes! Curved surfaces look tricky, but sewing patches on hats is totally doable. Go slow, use strong thread, and keep your stitches even. Embroidered and woven patches look especially good on caps and beanies.

Do sew-on patches work better for uniforms and workwear?

Yes. Uniforms get washed often and worn daily, so sew-on patches keep branding intact without peeling, cracking, or fading. That’s why businesses prefer sewn-on custom patches for work shirts, jackets, aprons, hi-vis gear and corporate clothing.

Why You Should Be Ordering Sew-On Patches (Like… Yesterday)

Sew-on patches are the backbone of reliable branding. They look sharp, last ages, and handle NZ’s wild weather better than most Kiwis in thongs at a winter BBQ.

And if you’re thinking of upgrading your brand, designs, or merch line, Patch Makers NZ is the best place to order custom patches, whether you need one, a hundred, or a thousand. Ready to stitch your story into your gear? Let’s get your custom patches made.